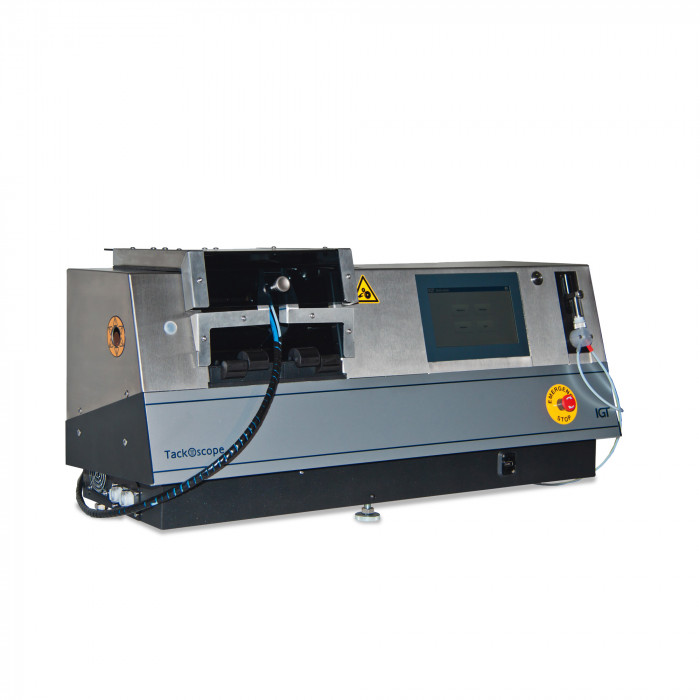

TackOscope-3 model LC

TackOscope 3LC: Instrument to measure the tackiness of a paste ink or varnish and/or to measure the emulsification behavior of a paste ink using different founts.

~~The IGT TackOscope measures the tack of printing inks and other pastes. Ink manufacturers, printers and suppliers of raw materials have to meet high quality standards, to ensure the quality of ink in a production and R & D environment. It is important to use an instrument that measures the tack of an ink in a quick and efficient way. High accuracy, low maintenance and simple operation ensure consistent results.

Applications

The IGT TackOscope measures the tack of ink and produces reproducible tack values. The Tack Tester uses a dedicated measuring system to measure the tack values of inks. Because of this system, measurements have become far more reliable and consistent than ever before.

Tack values are used by ink manufacturers to ensure the quality of the inks that are supplied to the graphic arts industry. For research the TackOscope is used to develop new inks. Suppliers of raw materials can ensure the quality of their products before these are supplied to their customers.

Because of the high repeatability and reproducibility of the tack values measured by the IGT TackOscope, it is an excellent instrument for use by many companies that operate on an international level. Tack values can be reliably exchanged between facilities to ensure a homogeneous quality throughout the world.

Compared to the TackOscope II the biggest changes are the build in computer and thermostatic waterbath. Besides this the TackOscope III has an automated roller lifting system on the measuring and distribution roller.

With these new features the repeatability and reproducibility have been improved and a fully automated operation is made possible. Furthermore there is the option to have the TackOscope III delivered with a build in LithOscope feature, the TackOscope III model LC. The LithOscope option of the TackOscope III LC allows for the automated (video) inspection and evaluation of the plate cleaning capacity of an emulsified. For this an accurately known volume of fount solution is brought into the ink as a mist of very small drops.

Measurement is fully automated using autolift funcion on measuring and distribution roller.The camera can detect the percentage the chromium strip is free from ink.

Applications

• Absolute tack

• Tack stability

• Fount/ink compatibility (LC model only)

• Opening offset plate (LC model only)

• Misting

Properties

The TackOscope III is foreseen with:

• Touch screen operation

• Internal computer

• Internal thermostatic water bath

• Autolift system on the measuring- and distribution roller

• Automated measuring system

• Quick release mechanism for both measuring and distribution roller

• Readout in Tack and/or Newton/m

• Optionally built-in LithOscope feature (TackOscope III LC)

Technical data

There are 2 different models available:

TackOscope III model SC – computerised model

TackOscope III model LC – as model SC but with built in LithOscope function

Specifications

Testing speeds : accurate speed control 0 – 350 m/min

Tack range : accurate tack measurement from 0 – 600 tack

Electrical connection:

110-115 or 230-350 V / 50-60 Hz

Dimensions (HxWxD):

330 x 800 x 300 mm

| Weight: | 73kg |

| Dimensions(L x W x H): | 0cm x 0cm x 0cm |

| Model: | 845.000.400 |

| Main application: | research and quality control tack emulsification behavior |

| Conformance with standards/W-leaflet: | ASTM-D4361, ISO12634 |

| Water bath and temperature: | internal water bath, 20 |

| Speed range and modes: | 5 |

| Forces: | 0-600 Tack units |

| Substrate requirements: | — |

| Interval time and number: | — |

| Printing shafts type and options: | — |

| Shaft positioning: | — |

| Lifting system: | Automatically |

| Print length and width: | — |

| Printing discs: | — |

| Sector positioning: | — |

| Sector type and options: | — |

| Doctoring system: | — |

| Dispensing system: | ink pipet |

| Pre-programmed tests: | yes |

| Analysis options: | Option, Tack Monitor |

| Interfaces: | USB port |

| Software updates: | Possible |

| Data export options: | Dedicated USB stick |

| Additional items: | UV measuring and distribution roller calibration set |

| Accessories: | — |

| Inks or liquids: | Most solvent based inks, some water based inks, varnishes, some adhesives |

| Inking speeds: | — |

| Inking programs: | — |

| Top rollers: | Rubber for conventional inks rubber for UV-inks |

| Maintenance: | Yearly. The annual maintenance and calibration of the tester can be carried out by IGT Testing Systems or companies authorized by IGT Testing Systems. Information can be obtained from your supplier or the local agent. |

| Compatible instruments: | TackOscope-3 SC TackOscope-1 improved TackOscope-2 partly TackTester 450 |

| Measurement range: | 0-600 Tack units |

| Light source/ power/angle: | — |

| Volume: | 0,4 cm_ |

| Shelf life: | — |

| Use life: | — |

| Description of property: | — |

| Cleaning: | with Starwash and Ethanol |

| Power Supply Requirements: | 115 or 230 VAC, 50 |

| Guarantee: | Standard one year |

| Space requirements: | 0.7 m_ |

| Standard delivery time: | 1-2 weeks |